XERAFY MICRO Paint Shop per temperature fino a 250 ° C, Paint shop skids, Chemical Pre-Treatments, Chemical Pre-Treatments, Cataphoresis coating, Hi-Temp drying ovens, Powder coating

Best For The Paint Shop

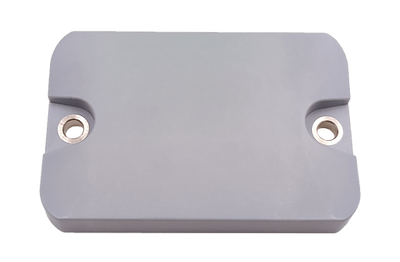

The Xerafy MICRO Paint Shop offers an on metal RFID tagging solution for cycling through high temperatures, fluids, and chemicals.

The silicone-free design eliminates the risk of contamination in the shop, and the rugged RFID tag’s IP68 rating and survival at 250°C ensure its durability.

High Temperature RFID Tags That Stand Out

The MICRO series from Xerafy offers the ultimate on metal high temperature RFID tags, providing consistent performance where reliability and durability are critical.

As Xerafy’s leading rugged RFID tags engineered for high temperature on metal tracking, the MICRO series offers durable and reusable tagging alternatives to barcode labels, making them suitable for a wide range of industrial assets.

The waterproof tags use a combination of packaging and casing materials to protect the RFID chip from heat, shocks, corrosion, pressure, and water.

What are UHF RFID tags?

UHF RFID (Ultra High Frequency Radio-Frequency Identification) tags are a type of RFID technology that operates at RFID frequencies between 300 MHz and 3 GHz.

The tags consist of a small antenna and a microchip that stores data about the object being tagged. When the tag is within range of an RFID reader, the reader sends a signal to the tag, which responds with its unique identification number and any other data programmed into the chip.

This information can then be used to track and manage the tagged object.

Unlike barcodes, UHF RFID allows for reading and writing data in bulk, in seconds, from a distance, and out of sight, thus enabling automated asset tracking.

Applications of MICRO Paint Shop

Paint shop skids

Chemical Pre-Treatments

Cataphoresis coating

Hi-Temp drying ovens

Powder coating

Technical Specifications of MICRO Paint Shop

| RF protocol EPC global Class 1 Gen2 | |

| Frequency | 902-928 (US) ; 865-868 (EU) |

| IC type (chip)1 | Alien Higgs-3 |

| Memory | 96-EPC bits, 64-bit unique TID, 512 -bit user memory |

| Material | High-performance engineered polymer |

SELECT THE PRODUCT OF MICRO Series