RFID-based tool tracking systems play a vital role in streamlining operations across industries such as aerospace, manufacturing, construction, healthcare, energy and utilities.

Xerafy’s tool tracking solutions are built on advanced RFID technology, offering robust performance for industrial applications.

RFID systems is used in critical operations like aerospace, where missing tools and maintenance (MRO) errors can lead to disasters.

technical specifications

- RF Protocol: EPC Global Class 1 Gen2.

- Frequency: Operates in the UHF range, typically 902-928 MHz (US) and 865-868 MHz (EU).

- Tag Materials: High-performance engineered polymers for durability, including resistance to high temperatures, caustic chemicals, and physical shocks.

- Tag Types: Options include on-metal tags, embeddable tags, and ruggedized tags for harsh environments.

- Memory: Tags feature user memory (e.g., 2K-bit) and unique TID (e.g., 256-bit).

- Durability: IP68-rated for water and dust resistance.

- Reader Compatibility: Works with fixed and handheld RFID readers for versatile deployment.

RFID technology is utilized

Xerafy’s tool tracking solutions have a wide range of applications across various industries.

- Aerospace: Ensuring compliance with FAA regulations and preventing Foreign Object Debris (FOD) incidents during maintenance operations.

- Manufacturing: Streamlining tool inventory management and optimizing maintenance schedules to reduce downtime.

- Construction: Enhancing accountability and safety by tracking tools and equipment on-site.

- Energy and Utilities: Monitoring tools used in high-risk environments like nuclear plants or oil rigs.

- Healthcare: Managing surgical instruments and medical equipment to maintain sterility and improve operational efficiency.

You can explore more about their applications here or here.

These specifications make Xerafy’s tool tracking system ideal for industries like aerospace, manufacturing, and energy. You can explore more details here or here. Let me know if you’d like to dive deeper into any specific aspect!

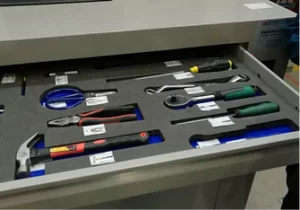

Aerospace tool control procedures traditionally rely on visual tool identifications such as tool foam organizers for toolboxes and drawers. Tool cribs and sign-in/sign-out procedures provide another level of control but with limited efficacy and accuracy.

Aircraft MRO operations have been early adopters of tool crib software and solutions, setting the standard for how other industries can address their own safety, compliance, and productivity challenges.

Automated Tool Control (ATC) solutions are now available that bring tool control RFID systems to drive safety, efficiency, and digitization.

The ATC solutions are built around multiple smart RFID-enabled mobile and fixed tool storage options, including tool crib, tool trolley, tool cart, tool cabinet, CICO kiosk, tool room, toolbox.

Lascia un commento